Scroll ⇩ to 'Meet Our Team'

With over 20 years of R&D, the NCSIMUL G-code verification technology has become a combination of the highest performance simulation software available on the market and the standard for "ease of use" in today's software offerings.

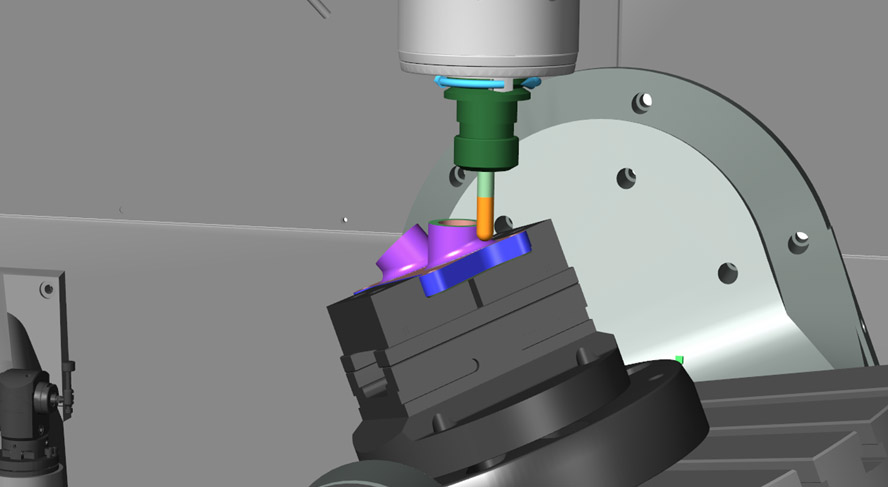

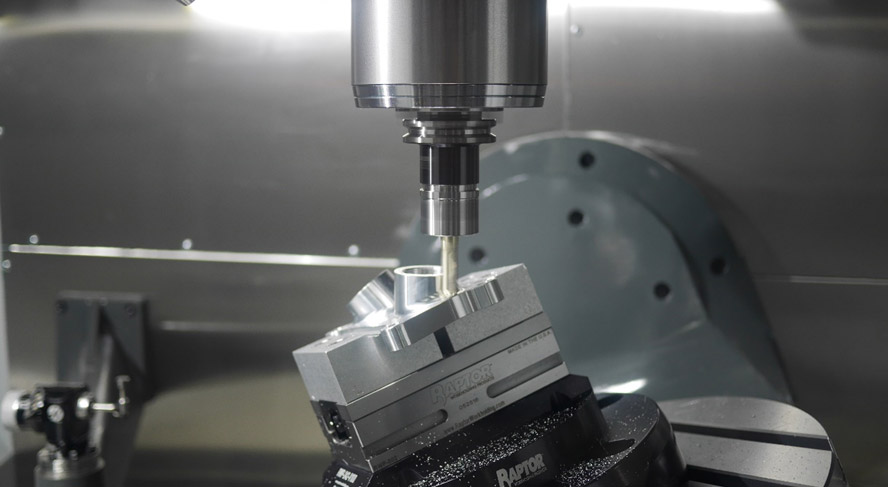

Available for turning, drilling, milling (3 to 5 axis), multi-tasking or even more complex machining, NCSIMUL Machine is the most advanced machining verification software for simulating, verifying and optimizing CNC programs. Based on the real characteristics of your CNC machine, the result is a dynamic verification software that includes the exact environment for all machines, tools and materials.

"Countless man and machine hours are saved, since we don't have to verify step by step on the machine"

Dean Dancer, Manufacturing Manager at Hutchinson Inc.

While the practical interface demonstrates CNC collision detection using crisp 3D graphics in real time, the powerful attributes of the software provide optimization of cutting tool feeds and speeds to reduce the parts' cycle time.

Collaboration in the workshop is also possible thanks to an embedded function that generates CNC technical documents, which can be shared and reviewed, along with the simulation, on NCSIMUL player.

NCSIMUL Machine is available as a standalone software, scalable to your needs. It facilitates your CNC verification process and tightly integrates your IT system through CAD/CAM interfaces. One of the key benefits, for example, is that any existing CAM data can be seamlessly imported into the software, eliminating the need to rebuild tool libraries.

If your company runs CNC machines, such as 5-axis or more complex machines, seriously consider NCSIMUL Machine to save time and money with better quality results:

You experience collisions

☑ You spend too many hours running the program block-by-block

☑ You waste time air cutting

☑ You break costly tools, spindles & other machine fixtures

Safe and collision-free machining

☑ Avoid CNC downtime

☑ Prove out G-Codes on your computer before machining

☑ Optimize your toolpaths

☑ Run your machines unattended

☑ Read and simulate any G-Code and machine tool builder macros.

☑ Preview tool path and detect errors before simulation.

☑ Interact easily between 3D window, G-code program, and information windows.

☑ Preview machine movements and material removal with graphical 3D technology and dynamic zoom capabilities.

☑ No machine is too complex: NCSIMUL Machine supports an unlimited number of channels.

☑ Launch all major verification tasks from a single screen.

☑ Turnkey solution which includes machine license, service and support at no additional cost.

Discover our holistic approach to eMobility