Scroll ⇩ to 'Meet Our Team'

GF Machining Solutions’ CUT 1000 series, specifically designed to meet micro dimensions demands, offers unique features in terms of precision and productivity, and perfect predictability and repeatability of machining results.

Deliver the highest precision parts with CUT 1000 series' X-treme precision version. The innovative mechanical structure of the CUT 1000 and a consistent separation of the sources of heat from the EDM area, kept constantly under water, as well as an optimal water circuit ensure the prerequisites for outstanding results.

Automate your productivity and use large wire for fast, cost-effective roughing, while machining with thin wire to cut fine radii at the best precision. Control the part from design to quality control with a complete integrated solution.

Simplify your manufacturing process with the ultra-flexible machine and HMI concept and reduce delivery time to your customers. Increase reactivity and take urgent jobs or change your day and night strategies on the fly.

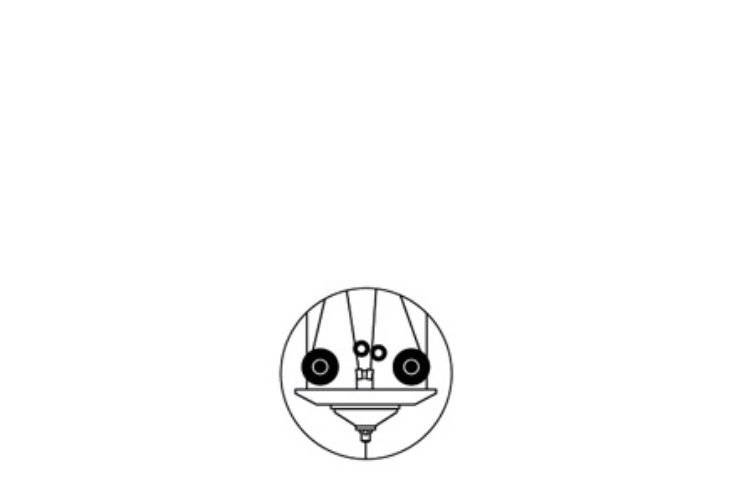

Experience superior mechanical stability and precision across the life of the die-sinking EDM machine, thanks to its short C axis construction and oversize cast iron frame. As a result, your accuracy is uncompromised by part weight or dielectric volume and your precision is further advanced.

To obtain reliable positioning accuracy, only linear glass scales are effective. They eliminate all the classic errors, such as backlash, expansion and wear effects. The axis servo control system developed by GF Machining Solutions for die-sinking EDM machines is a closed loop measurement solution designed to provide infallible accuracy, whatever the travel.

Parts machined on the CUT 1000 OilTech have exceptional surface quality. There is no coloration due to oxidation or redeposit of materials suspended in the dielectric.

Get the perfect solution for luxury watches.The machined parts are sound and without defect, ready to be used, aesthetically perfect, and of exceptional quality, meeting the very high demands of the watch making industry..