Scroll ⇩ to 'Meet Our Team'

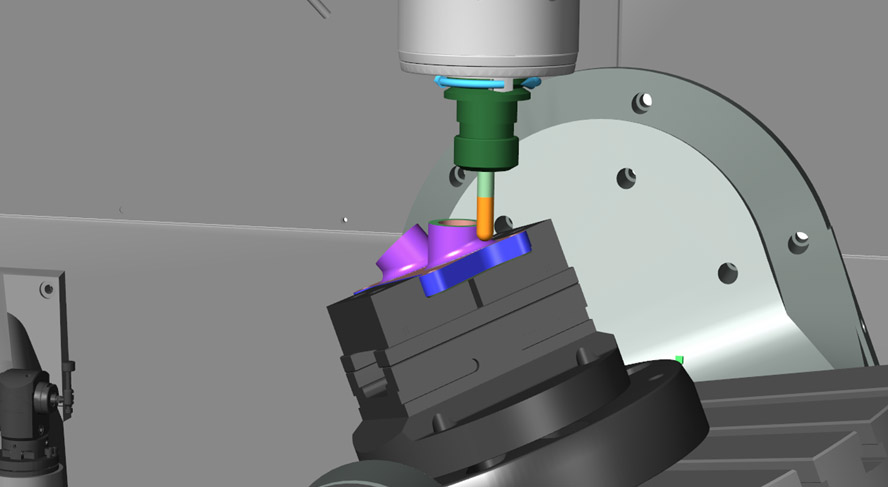

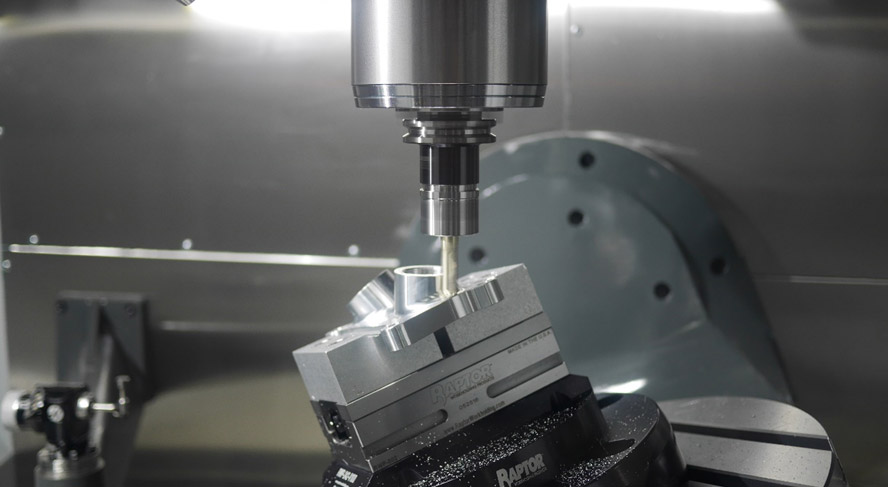

NCSIMUL 4CAM is enriching the existing CAM process to simplify CNC programming. It provides unparalleled flexibility on the shopfloor. It allows to change, in one click, the target machine, without any CAM reprogramming.

From the main CAM (CATIA, NX, Creo, TOPSOLID CAM, MASTERCAM, ...) or existing CNC programs (G-code format), NCSIMUL 4CAM generates directly, without external post-processor, CNC native programs, verified and optimized taking into account the physical means of the workshop (tools, cutting conditions, kinematics, machine controllers ...)

You experience collisions

☑ Re-write and re-work former CNC programs for new machines without reprogramming

☑ Switch part production between machines at the last minute

☑ Re-engineer some of your toolpaths and need to reprogram

☑ Develop and maintain specific post processors to generate G-code programs

☑ Capitalize changes to your G-code program

Generate automatically new CNC machine programs from a formally created CNC toolpath

☑ Switch your part machining between the different CNC's, on-the-fly, without reprogramming

☑ Reuse existing APT or G-code files with just a copy/paste click, to optimize the manufacturing process

☑ Eliminate external postprocessors thanks to the integrated CNC processor

☑ Connections between machine sequences are automatically calculated in an optimal way

☑ « Hybrid » programming, for a seamless legacy program recovery

☑ Error-free native CNC code programming, as an all-in-one solution

☑ No more external postprocessor, streamlining the CNC process

☑ One-click re-programming, for complete flexibility

☑ Dynamic rest material management, for a peerless programming comfort

Discover our holistic approach to eMobility