CAQ – Quality Management

Detail view with OEE, MTTR, MTBF and runtime diagram

Overview

Measurement equipment management

In the test equipment management all test and measuring equipment is recorded according to standards. The inspection dates are monitored. Test equipment due for testing is summarised in a list. Test costs can be logged and analysed.

Inspection equipment capability

Test equipment capability investigations may be carried out in accordance with standard procedure 1, 2 and 3.

Test equipment monitoring

The test equipment monitoring supports the user during calibration according to standardized test specifications such as VDI/VDE/DGO2618. Individual test plans can also be created.

Conversion of a drawing in an inspection plan

Test plans can be created graphically interactively. Different test criteria can be defined for each operation.

Initial sample test report

The release procedures according to VDA 2 (PPF) and QS 9000 (PPAP) include both product and production process release.

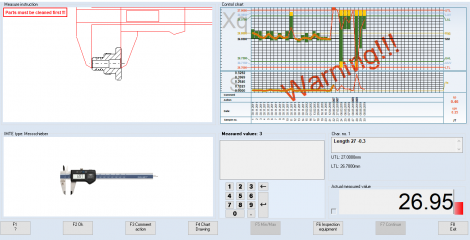

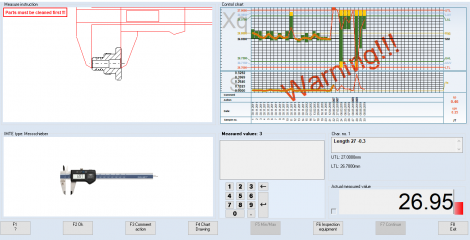

Measuring data acquisition

The operator is guided through the measuring sequence by the software. He is shown how to measure. If the test equipment is connected to the system via a measuring multiplexer, the measurement data is automatically recorded. 3D measuring machines can be integrated just as easily as measuring systems installed in the system.

SPC (statistical process control)

The statistics module supports all relevant distribution types. Many evaluation forms are already available.

Complaints management

For internal and external complaints, including 8D report. An internal complaint can be generated directly if a measurement criteria is violated.

FMEA

With knowledge database

CAPA

APQP

Workflow and measure management

The measure management can be used across modules. The status of each measure can be seen in the measure cockpit. Measures can be controlled via the workflow module. Standardized processes can thus be initiated at the push of a button.

Audit management

The existing audit catalogues can be added very easily.

Effective quality management

CAQ 5000 is a modular computer-aided quality management system, fully integrated with interfaces to 3rd party systems e.g. ERP. A consistent data management avoids double entry of the same data. Measured data are automatically stored and assigned to the appropriate customer order.

The modular design of CAQ 5000 closes the gaps in an existing Q system. If required, the CAQ solution can be expanded at any time.

CAQ 5000 stops the flood of paper, reduces quality assurance efforts and sustainably improves processes in terms of quality. With its simple, efficient handling, CAQ 5000 is ahead of its competition.

The CAQ solution covers the entire quality process. Measures can be derived directly from the various CAQ modules, which can then be monitored. And if necessary, an escalation is triggered. Since the modules interact and access the same data, you simply move through the modules and traceability is guaranteed.

CAQ 5000 has various interfaces. The interface between ERP and CAQ is one of the most important. Master data and transaction data are maintained in the ERP and can be used by the CAQ. Measuring machines, measuring bridges and measuring systems can also be integrated into the process. The QDX interface and the calibration interface according to VDI 2623 enable electronic data exchange with third parties.

Detail view with OEE, MTTR, MTBF and runtime diagram

Detail view with OEE, MTTR, MTBF and runtime diagram