Scroll ⇩ to 'Meet Our Team'

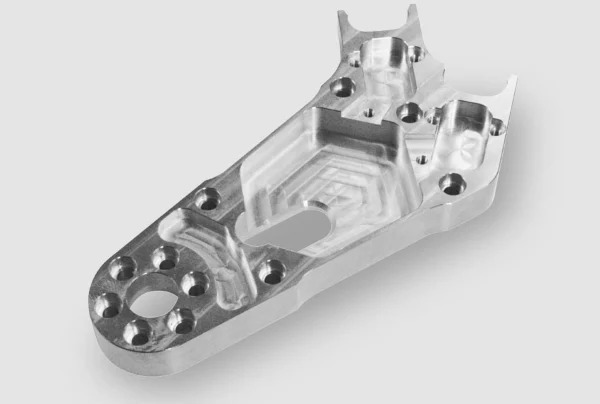

The foundation of modern manufacturing, 3-axis vertical CNC milling machines use rotary tools for efficient material removal. As the pioneers in high-speed 3-axis milling, GF Machining Solutions offers a comprehensive range of CNC milling machines with the speed, power, performance and dynamics necessary for manufacturers. And thanks to a complete catalog of compatible automation systems and optional features, each 3-axis CNC machine from GF Machining Solutions can be customized to fit any shop’s needs.

Based on our 4P business philosophy, we strive to be your longterm partner by planning and providing the specific technology solution and supporting you throughout the entire machine lifecycle for maximized profitability.

Ultra-high-speed machining performance and reliability for superior surface finishes and precise tolerances

The high-speed milling solution that set the standard for performance and precision

Reliably exceptional performance with uncompromising process security

Guide you to the top

Expand your expectation through an efficient production in universal applications

High speed milling in compact format

Maximum efficiency. Flexible functionality. Peak productivity. The Mikron MILL X series of ultra-high-speed vertical 3-axis CNC machining centers brings together a range of sophisticated internal systems, state-of-the-art design features, best-in-class spindles and an integrated automation system. World-class machine dynamics and a portal-style design built for the highest rigidity make these machines perfect for the serial production of precision molds, dies and parts.

The industry’s leading series of high-speed milling solutions, the Mikron MILL S series of 3-axis vertical CNC milling machines let any manufacturer meet the challenge of delivering speed and quality at the highest level. Integrated automation and measuring systems, smart machine modules, world-class controls and unrivaled machine stability allow for reliable processes, the fastest cycle times and the best surface finishes.

As an important part of the turnkey solution, we develop and provide an application specific process concept including the tooling and fixturing concept leading for cost efficient and high quality production.

Across a wide range of market segments the Mikron MILL P 900 vertical, three-axis Milling machine delivers quality, competitiveness, productivity and efficiency to a broad range of applications.With its robust portal structure featuring high dynamic stiffness, this solution is especially designed for mold, die and part producers who are looking for the best surface quality and very high positioning and contour accuracy.

The Mikron Graphite Series is a high-speed Milling machine series dedicated to graphite machining. With its experience in tough high-speed Milling in combination with a dedicated three-axis graphite machine, GF MS provides the optimum solution for dry graphite Milling. The unique design provides clean, dry graphite machining for high accuracy, surface quality and dynamic processing.

The comprehensive range of options available for the MILL E and VCE Pro series makes it simple to put together the manufacturing solution that’s ideal for your shop’s needs. Three cartridge-type belt-driven spindle options make it easy to find the MILL E or VCE Pro series solution ideal for your shop – and Step-Tec Spindle technology means quiet, smooth performance and outstanding reliability.

The industry’s leading series of high-speed milling solutions, the Mikron HSM 500 3-axis vertical CNC milling machines let any manufacturer meet the challenge of delivering speed and quality at the highest level. Integrated automation and measuring systems, smart machine modules, world-class controls and unrivaled machine stability allow for reliable processes, the fastest cycle times and the best surface finishes. Ideal for small precision components in the watchmaking, electronics, machining, and information and communications technology industries, the Mikron HSM 500 handles complex tool paths and high feed rates for the surface finishes and part quality required for part and mold production.